Products

Mold - Taper

e-Taper

Importance of Taper

For making the billets with high quality, it is important to keep equalized cooling inside of mold.

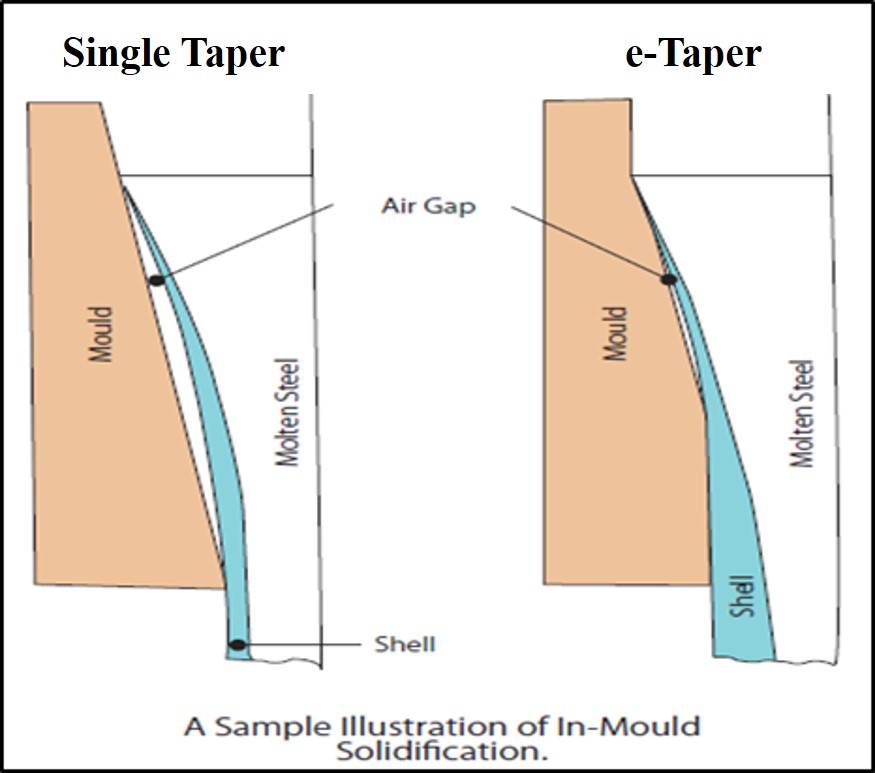

It is necessary to make the air gap between the inner wall of the mold and the billet as small as possible to make high quality billets.

Since the thermal conductivity of air is extremely low compared to copper, the air gap impedes heat transfer and causes uneven cooling, which in turn causes rhomboidity.

e-Taper

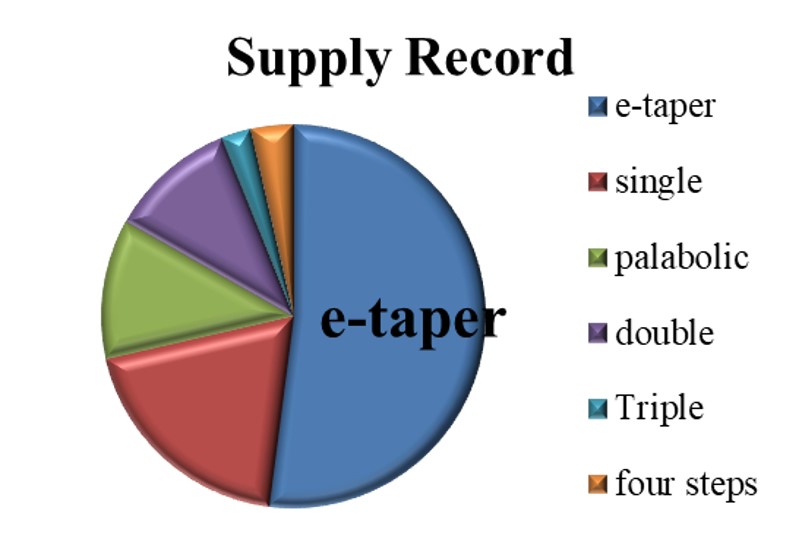

The ideal taper will be designed by the continuous casting heat transfer calculation software that was jointly developed by our company and Fukuoka Industrial Technology Center.

By proceeding the solidification simulation based on the casting condition (patameter) of customer, the ideal taper will be designed to have minimuma air gap.

- -Minimizing the air gap ensures that the billet is in contact with the inner wall of the mold constantly, and it result in evened cooling and have a thick and strong shell.

- As a result, breakouts and corner cracks can also be reduced.

- By improving the cooling effect, the casting speed can be increased and that helps improve productivity at well.