Products

Mold - Heat-resistant alloy

Materials and their characteristics

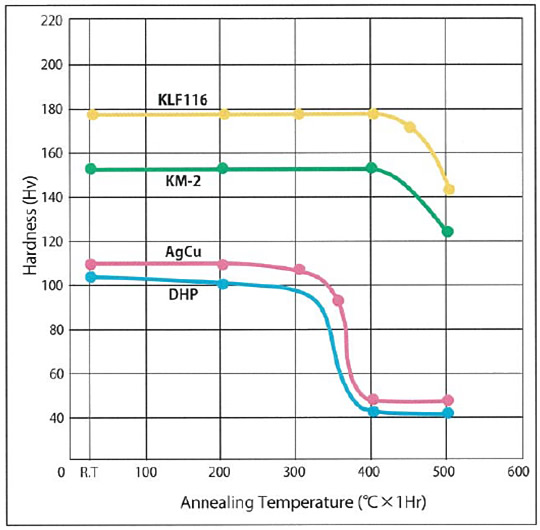

- High phosphorous deoxidized copper

- Normal deoxidized copper, readily available on the market.

- Silver-bearing copper

- Through the addition of about 0.1% silver, strength is signicantly enhanced with non loss in thermal conductivity, compared to deoxidized copper/ the softening temperature is also about 100degrees Contigrade higher than deoxidized copper.

- KM-2

- Cr and Zr precipitation hardening provides this alloy with high strength, high resistance to heat, and thermal conductivity as high as high-phosphorus deoxidized copper.

- KLF116

- Developed for electromagnetic stirrers, this alloy offers reduced electrical conductivity to minimize current loss in use. Ni2Si precipitation hardening provides strength and heat resistance superior to KM-2 alloy, and the addition of Zn enhances platability significantly.

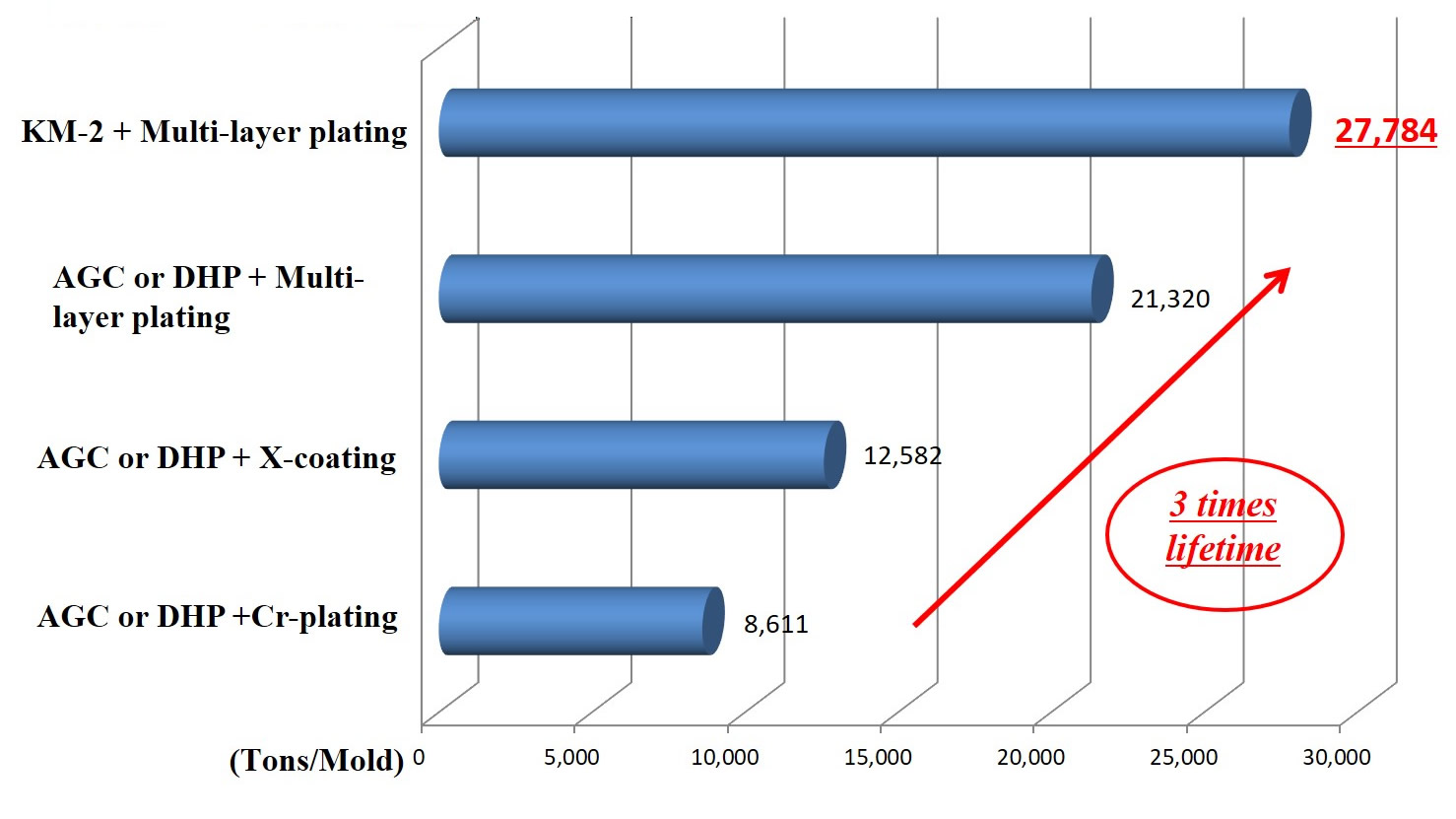

Average Mold lifetime(Tons/Mold)

- ※The above results are based on the same environmental conditions that combine our plating with the alloys introduced.

It varies depending on each operating condition and operating environment, and this does not guarantee the lifetime.