Products

Mold - Wear-resistant plating

Wear-resistant plating

Importance of plating

In order to maintain the production of high-quality billets, it is important not to break the inner shape.

Since molds are used under very severe conditions, the inner surface continues to wear out.

Therefore, it is possible to reduce and maintain wear by applying wear-resistant plating to the inner surface. In some cases, we will investigate the used mold of customer and select the appropriate plating.

Lineup of plating

- ①Hard Cr-plating

- This is a common hard Cr plating.

Mold lifetime↑

- ②S-Cr plating

- This is a plating that reduces the through cracks peculiar to hard Cr plating.

Mold lifetime↑↑

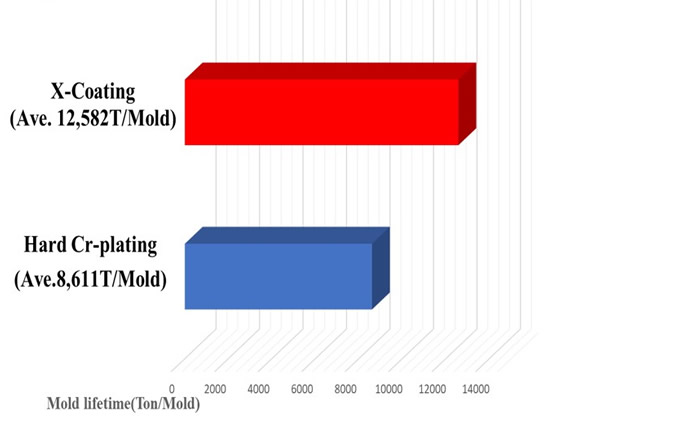

- ③X-Coating

- We have developed Cr plating with less cracks by adopting a method that greatly changed the concept of hard Cr plating.

Mold lifetime↑↑↑

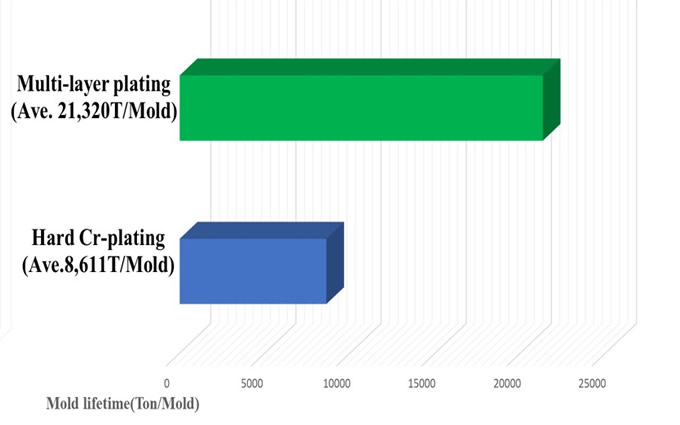

- ④Multi-layer plating

- By making our original plating with multi-layer structure, it has the highest wear resistance in our company and it is about 2.5 times more durable than hard Cr plating.

Mold lifetime↑↑↑↑

- ※It varies depending on each operating condition and operating environment, and this does not guarantee the lifetime.

Mold lifetime

Estimated lifetime

X-Coating ≒ Hard Cr plating x 1.5

Multi-layer plating ≒ Hard Cr plating x 2.5

- ※The above results are based on the same environmental conditions that combine our plating with our alloys.

It varies depending on each operating condition and operating environment, and this does not guarantee the lifetime.