Products

Heat Exchanger

As the one of the company who studied and worked the first practical application of Titaniumin in Japan, we focused and developed Titanium which has exellent corrosion resistance as material for heat exchanger in the harsh condition.

After that, we gain various experience and supply records then we developed vrious type of heat exchanger such as「Double-tube type heat exchangers with groove」「Shell and tube type」「Coil type」adjusting the purpose of use and scale. These products got high evaluation from the customer of verious application such as Food cooling, Cultivated for fisheries, Boring, some inddustrial use.

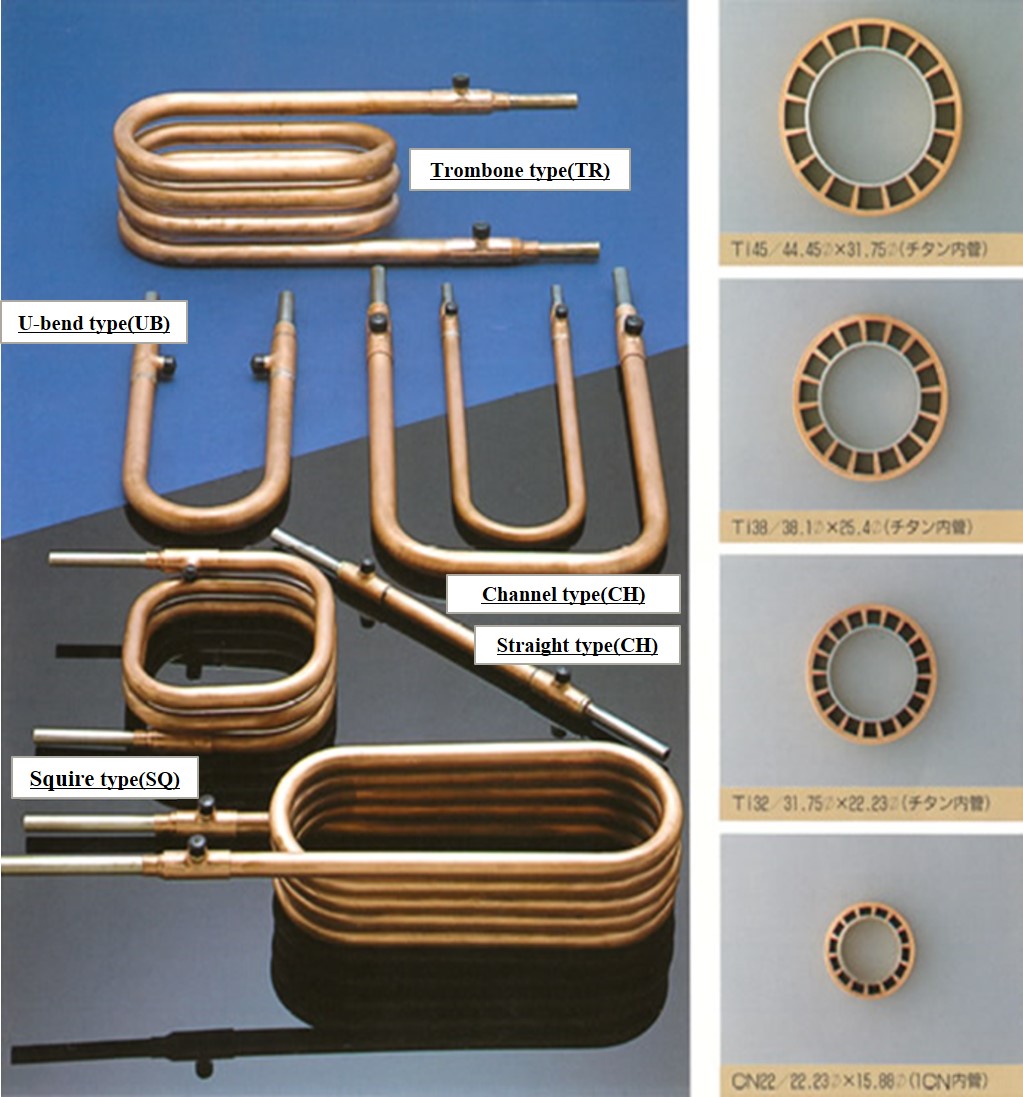

Double-tube type heat exchangers with groove

High poerformance

By fin's effect, the heat-transfer area at refrigerant-side would be increased, and refrigerant-flow would be uniformed. These enhance the heat exchange efficiency to 5~10times.

Conpact

This heat exchanger is piped type, and it may reduce the surplus space of refrigerant system.

Multi-application

Since various material such as Titanium・Copper-nickel・Copper are adopted for inner tube, our heat exhanger can be used in multi-application.

Lineup of Double-tube type heat exchangers with groove

- Type 45

- Type 38

- Type 32

- Type 22

- Outside diameter of outer tube(㎜)

- 44.45

- 38.1

- 31.75

- 22.23

- Outside diameter of inner tube(㎜)

- 31.75

- 25.4

- 22.23

- 15.88

- Material of outer tube

- Copper

- Material of inner tube

- Titanium / Copper-nickel / Copper

- Inner tube fitting

- Titanium nipple / SUS loose-flange etc

Introduction

You may select 3 materials(Ti, CN, CU) for inner tube, 4 sizes for inner tube(Type45, Type38, Type32, Type22) for your use.

About the shape, there are 5 unit-type (Straight type(ST)・U-bend type(UB)・Channel type(CH)・Square type(SQ)・Trombone type(TR).

Titanium type Heat Exchanger

High corrosion resistance

Titanium has higher corrosion resistance to corrosive solutions and seawater than other metals. It is most suitable for various industrial cold water equipment and food cold water equipment.

Lightweight and compact

Compared to stainless steel, titanium has a specific gravity of 60% and is thinner.In the case of titanium coil type heat exchanger, the heat exchange weight is as light as 1/4 to 1/10.

Suitable heat exchanger design

We design and manufacture heat exchangers that are suitable in size and shape according to customer needs.

Example of applications

Double-tube type heat exchangers with groove

- Cooling device of special solution

- Water cooling device for shipment

- Boring cooling device

- Low temperature water cooling device for food

- Liquid temperature control unit of plating layer

- Water cooling condencer

- Device of refrigerant cover cooling / over heating

- Cooling unit for inudustrial machine

- Oil cooling unit

All titanium 1-passing unit(Straight tube type)

- Seawater heating machine for aquaculture

- Warm water heating machine

- Econamyther

- Heating machine for waterworks

- Heating / Cooling device for food

- Waste heat recovery device

- Hot water supply

- Gas heating device

- Defumidification device

Titanium Coil type heat exchanger

- For aquaculture

- For sludge treatment

- For aquarium fish sink

- For live fish sink

- For heat exchanger of waste heat recovery

- For air condenser of poultry farm

- For air condenser of animal products

- For greenhouse cultivation

- For hydroponics

Titan

- For live fish sink

- For defrost device of frozen fish/meet

- For cooling device of seaweed

- For cooling device of noodles